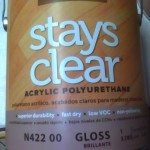

Being a member of the Benjamin Moore PAB, I sometimes get products to review before they are released to the market. About six months ago I was selected to review BENWOOD Stays Clear, the newest gennex line of low VOC waterborne polyurethane. I had a lot of experience using the old line of stays clear on both wood flooring, furniture, and trim for many years. It was an easy to apply clear that dried very quickly and would harden after a two week cure. I like it so much that I chose to use it on my own oak flooring when I refinished it five years ago.

It has held up very well to lots of traffic, but could use a fresh coat. That is a wonderful thing about this product, you can scuff sand and re-coat easily. I was excited to try out the new formula, and am pleased to see some improvements in the hardness, and application. I applied to some oil stained birch bead board wainscot with my hvlp with a 2.0 tip reducing only with water by 10%. Finish applied easily without any fisheye issues or separation of the finish you find in many wb clears. Outstanding finish in this application and I wouldn’t hesitate to use it again.

My next test was for red oak. I was sampling some for a local builder and decided I would try it along with some oil base poly that was spec’ed. Below are some progression pics as I built the finish up in high gloss. The sample oak had not been planed, so it wasn’t as flat as possible and there were some chatter marks there from the mill. This was clear grade red oak, and I have to say I was extremely pleased with the outcome. The owner and builder both were so impressed they decided to go with the wb over oil after reviewing the samples.

Sanding between coats was tough, and even more so after I achieved a good film build. I had to get very aggressive hand sanding as I progressed to 180 grit to remove any material or even scuff the finish. It did come to a very acceptable flatness after the fourth coat however, and I feel confident this coating will perform wonderfully with regard to durability as a flooring clear. So all you finishers out there keep and eye out for when its released, and give it a go yourself. I hope you are as pleased as I was.

I welcome your feedback or questions you may have, and would be happy to share my experiences in the comments below.

Thanks Tommy. It’s always good to know there are good products out there that some may not know about. I’ll have to give this product a try.

I was a huge fan of the original too but back then we were doing 95% stain work. Today, we do 95% painted. Good to hear the product has maintained a good position. I too finished oak floors with it. Wow that was so long ago. I remember posting a review on the product because it was one of the few product that wouldn’t turn oak dark from traditional oil-based clears. Loved that product! Easy application and leveling.

Thanks Tommy.

Tommy, good testing. Thanks for sharing. Its great to see reliable reviews in which months of observation are spent. It takes months to really track a product, especially a paint product. I cringe when guys “review” immediately after applying – its just not reliable or meaningful at that point. We have a goodbunch of serious snobs in this blogging group!

I always want to do more, but without waiting a year of more to review a product there isn’t any way for me to do that.

I really liked how incredibly hard this product got. I didn’t include it in the article, but I applied some to factory primed mdf and it was like holding a piece of real wood after it cured.

Little things you feel and sense are hard to include in your reviews, but you know what they will do to the longevity of a finish.

Thanks Tommy for the review, it leveled out beautifully! 🙂

It did turn out nice didn’t it. I think I will be giving my floors a fresh coat soon. My office really needs it where the computer chair is, and down the hallway.

The bedrooms still look great after five years now.

Question, we are getting knotty pine doors for our cowboy church, I want to keep the natural look to the doors do you think this product would be good to finish the doors with and how many coats do you think they would need? Thank you

Does it still have a bluish cast over dark stain?

It does slightly change the stain color, not quite as significant as with the original however.

I was using a dark red walnut in my tests. I was more pleased to not see any fisheye or separation issues.

Hi, I just saw this review and have a question. We are painting our outdated oak cabinets and we used a latex paint and primer combination. We were going to use Minwax clear satin poly over the paint, but were concerned about yellowing, so we bought the Benmoore Stays Clear, which was not cheap, and we have only done 3 cabinet doors and they are yellowed just overnight. Should it make a difference putting it over stained wood or paint? Should we have stuck with the Minwax or not worried about putting a poly on at all?

Anna let me see if I understand your situation correctly. You painted the cabinets with a coating, and then applied Stays Clear as a finish coat?

If that is correct, what paint type and brand of paint was applied first?

Stays Clear is a waterborne product, and doesn’t yellow over time like traditional oil base polyurethane. So unless you had an incompatible paint applied first then I don’t know why it would do this.

We sanded the cabinets first and then we applied 3 coats of Behr paint/primer combination in eggshell. We did 3 cabinet doors with the Stays Clear and all three of those need to be sanded again they are so yellow. Does it make a difference if we put it on too thick…we tried to make it as thin as possible and were going to do 2 coats. My husband then tried diluting it 1:1 and rubbed it on a 4th door and it was a lot better, but there were still a couple really light yellow streaks. I don’t know what else to do. Any thoughts?

Anna, I am stumped to be honest. When you first apply a wb clear, and even looking at it in the can there is usually a milky blue tint. You can see this illustrated in the fifth picture in the article above. I applied that coat very heavy. The milky color is normal, and as the coating dries it will become clear.

I would suggest taking one of the cabinet doors that are yellowing to the paint store and have them look at it.

Doubtful Behr eggshell paint should be causing this kind of reaction with Stays Clear.

I took the doors to the local paint store where I bought the Stays Clear (we bought the Behr paint at a Home Depot about 45 minutes away). She is pretty set on proving that it is the paint and not the Stays Clear, so we will see tomorrow. She put some more on one of our doors and then some on a paint stick with white paint on it to see what happens. We are ready to just scrap the whole poly thing and just put on a coat of semi-gloss or satin to get the sheen I want and be done with it. I realize that it is just added protection, but is putting poly on really necessary? Thank you for all your feedback by the way. I really appreciate it.

I’m having the same problem with behr paint, and the Stays clear yellowing after application – i tried the minwax first, it did the same, so I went to Ben Moore stays clear, and same result, though less yellow . . .Im wondering if its the Behr paint?

Anna I thought about this today, and it is possible that the clear is somehow lifting colorant like yellow oxide from the paint below and causing it to dry yellow. How long did you wait to apply the Stays Clear after painting them? With many interior paints you can wet a clean white cloth and lift color from the finish up to two weeks after application.

For cabinets I would have chosen a different product. That is unless I was doing a distressed look, and or glazing with the base coat that required the use of a clear coat finish.

If you do decide to paint then a durable tough enamel is what you want to use. Benjamin Moore has a great new product called Advance that I like, and really produces a beautiful finish.

Yeah, I think we put on the 3rd coat of paint on Sunday or Monday and put on the Stays Clear on Tuesday, so we didn’t wait long enough. We didn’t know that that would happen or that we had to wait. Oh well I guess. Thank you for all your help!

For cabinets what product would you use? I did a light paint job on my raw oak cabinets to show some of the grain in a matte white paint from benjamin moore. now I want to spray a portective coat overtop, and I wanted to use stays clear. any other ideas?

Happy to help Anna. Let us know how you project turns out. We love pictures as well!

I suspect that ammonia is the issue here. The Behring coating has a high ammonia content and the Stays Clear may have attacked a curing paint and reacted with the ammonias causing the acrylic to yellow. Was any other painting going on during the application of Stays Clear? We’re any alkyd based coatings present? Uncured alkyds will also turn acrylics yellow. For example: if an oil based stain is used and a water based clear is applied too quickly, there is a chemical reaction between alkyds, acid and alcohol and the ammonia in the acrylic. There is a chemical reaction going on here I believe. Most acrylics dry gin clear unless applied to a cold surface, too thick, or condensation or moisture interferes with the curing mechanism.

how long should you let a painted piece cure before you apply the polycrylic, to prevent this yellowing? perhaps thats my problem

I have a question….My home has very old hardwood floors that were covered with carpet for many years and needs something to protect them. I am considering the stays clear with a semi gloss. I haven’t done any thing but apply mineral oil to them b/c they were very dried out. Now i’m not sure what stain is on them or if that even matters??? Would it be ok to just apply this with a roller and let the floor dry?? I’ve never done this before and don’t want to mess them up. any advise would be appreciated.

If you have used Mineral oil on the floor my concern would be compatibility and adhesion of the Stays Clear to the wood. I would clean the floor first with Simple Green, lightly sand if feasible, and apply a test area to insure compatibility. Mineral oil doesn’t really dry and the water in the Stays Clear may reject each other.

Thanks Jeff!

Frank, if you need more advice, may I suggest you post your question to the team over at Topcoat Review? They have a section just for this, http://topcoatreview.com/ask-the-topcoat-team/

Thanks for stopping in and let us know how it turns out!

I agree with Jeff, I would for sure test an area like a closet first. WB clears are finicky, and many things will often cause issues with adhesion.

thank you guys for the information. when i get it done i’ll post the results.

Has the product been changed recently? I am redoing my hardwood floors. A family member recommended minwax highgloss but when I went to the hardware store they only had flat in minwax. The clerk recommended the benjamin moore stay clear and that was only available in gloss. There was no choice between high gloss or low luster as seen on benjamin moore website.

My point being is I am on my 3rd coat on my floors and I am not getting a really high shine or a really baby butt smooth floor. Is this do to not using high gloss?

I was also thinking I may need to use higher grit sandpaper. I used an orbital sander with 24, 36, and 80 grit and then have hand sanded between each coat with 100 grit. Is 100 grit not high enough?

Thanks for any help or suggestions!!

Rachelle, I would wonder if you are applying enough with each coat. What is your application method?

Generally after three coats, and screen sanding with 150 grit between you have enough film build that sheen should be true.

The TDS technical data sheet recommended wet film thickness is 4 mils. I have applied heaver before, but it increases dry and cure time.

For application to floors I pour directly to the floor using a large cup with a pouring spout. Then spread the poly evenly with am applicator made for waterborne polyurethane such as this one.

http://www.lewiscontractorsales.com/Merchant2/merchant.mvc?Screen=PROD&Product_Code=13253&Category_Code=fabulon

Hi, I came across this review as the clerk at a Benjamin Moore shop recommended Benwood stay clear – Acrylic Polyurethane flat. Currently the wall under my kitchen island (facing the living room) is painted with decorator white in flat. Over the years, it got a lot of blue/black marks on the wall – from the jeans and shoes, which are not washable. I thought of repainting that section over decorate white – matte/eggshell finish (easier for cleaning). But he didn’t recommend as it will be noticeable in the living room, especially if I were to use eggshell finish. He said I might be able to get away just coat the wall with Benwood stay clear.

If I were to paint the wall with BW stay clear, would I notice the difference? Also is it safe to paint it over an interior paint, as most of the reviews that I read are done on wood.

Thanks in advance!

Tina,

He is correct that any change in sheen will effect the way you perceive the color. I wouldn’t think this fix would be the exact same sheen as your flat walls either, which would again effect color perception. You can test it and see, however painting under the bar and the adjoining room in a washable matte would be my suggestion.

Hi, I am a floorcloth artist and have been using Ben Moore paints for a long time, I’m a Ben Moore snob. I need to use the hardest yet flexible polyurethane which means a good acrylic poly. I’d been using Sher Clear by Sherwin Williams because it is an industrial water-based poly that remains extremely flexible yet very hard. Well the store I normally get it from didn’t have any and wasn’t going to be stocking it anymore so I thought I’d try Ben Moore’s new Acrylic polyurethane.

When I opened the can I noticed how thick it was and wondered if this is normal. It was difficult to paint onto the surface it was so thick and almost gloppy, didn’t spread to well. I also got low-luster which to me seems very high gloss. I did stir the can well. Is this normal or did I get a bad batch?

applied a first coat of Stays Clear and checked on it an hour later-litterally fell apart-like it stretched then tore. We used PPG colored paint with a base coat first and let each dry 24 hours. Temp is 70 with low humidity.

I do Love this product but we never thin and spray HVLP with a 3 or 4 tip. Do you recommend the 2 tip and thinning 10% for a finer finish? Also another quirk. It says on the can you can roll on. Tried on a sample cabinet door and it did not work… bubbles! and never leveled out. Did I do it wrong?

Karen we don’t thin I think you will want to start with a 4 and then see how it goes from there. What type or roller were you using? I have often seen this happen with wb clears, and especially with a foam roller.

I have just spent the last month of my life staining and Stay Clear-ing about 700 square feet of floors. I am pretty unimpressed by the ease of applying the stays clear; I don’t have a sprayer (and have heard this is the best way to apply the product) so have done it all by hand. Ouch! Was so hoping the roller would work- but, alas, as previous reviewer stated, millions of tinnnnny bubbles. Anyway,used a very nice Purdy brush as well as a Varathane brush. It becomes extremely gloppy after about 20 sq ft of work. I rinse wash well with soap and mineral spirits several times per section of my floors. Arg! I am very worried that my application, despite my best efforts, has been too thick. If this is the case, is my goose cooked? It has been 2 weeks and I can still make a mark with my finger nail if I press hard. Gulp :/

Meg, sorry to hear of your troubles, hopefully one of our readers or resident experts will chime in soon!

Megan it does indeed sound like you over applied. The most common application tool for flooring is a pad. It may eventually harden, I would tread lightly and give it a month and see.

I used stays clear high gloss on my newly installed cherry stair treads and risers. I did three coats and sanded between coats. It looks great except I was hoping for more of a red color.

Can I get the rest of my can tinted and do a fourth coat to try to add some color? I was told I should strip it back down to bare wood and start over.

HELP

You can try adding in a little color but your application technique must be spot on. Any overlaps will show a difference in color.

Tommy. We just did a very large commercial project using Stays Clear HG in a new firehouse. The wainscoting was stained first. The architect wanted it a little darker so we used BM Gennex tints to shade it to the custom stain color. A little challenging but it came out perfect and was accepted by the Architect.

Will I be applying the tint by itself, or should I have the stays clear tinted and do a fourth coat? Should I sand before I tint it

We tinted the Stays Clear. We did not sand since we did not want to effect the stain color and only needed one coat to get the right color.

Glad to hear you were able to save that job by shading. If I recall correctly stays clear can be tinted with up to two ounces of Gennex colorant.

Eric I would just scuff sand like you would between coats, since you have several on already burning through the finish wouldn’t be a concern.

If you do decide to shade it by adding colorant to the stays clear I would go light with the colorant and do more than one coat. Depending on how red you want them trying to darken it up all at once may leave you with a mess.

I assume you are brushing these?

My company is currently in the process of toning a stain job with dyes. We are spraying several coats of a weak dye mixture in a 50/50 cut seal coat. As long as your color change is slight I think simply adding in some red to the poly will work fine.

Basically we duplicated what was on the surface in a sample and then shades the stays clear in small increments until the architect and Fire Chief were satisfied. Lots of time but the job came out perfect and it solidified our reputation and gave us a lot more work and credibility.

Hello,

I’m hoping for a little advice. I’ve read through a number of responses here and you seem like the right people to ask. I’ve been having a heck of a time with my staircase, so much so that I had to scrap all my hard work and start again.

My local BM shop color matched a Zar stain to help me get my staircase (red oak) close to my new maple hardwood floors. The treads were sanded down to bare wood and a wood conditioner was applied before staining. It took a bunch of trips back to the shop to get the stain dark enough but I finally managed to get the color really close and it looked great.

The problem came in when I applied the BM Stays Clear Low Luster poly. It lightened and significantly changed the color of the stain, instead of the greyish brown that I had, it became a red/brown color. There was nothing I could do at that point so I had the remaining poly tinted. It worked and the color was spot on but wow, what a pain it was to work with. As Tommy previously mentioned, your technique has to be perfect and mine was not. It ended in an uneven mess on some steps.

Since I’m doing this all over again, I’m hoping to avoid this situation. A few questions:

1. Do you think the red color is coming in for the fact that this is red oak? Or might there be some other reason? My new plan is to stain darker since it got lighter after the poly and I’m hoping the red hue won’t show as much on a darker color. I’d rather have darker steps than lighter red-ish ones, does this sound like it would work? I won’t be going the tint route again.

2. Should I start with a wood conditioner? It took me about 4 rounds of stain to get the wood to take on the color I wanted (possibly more). The wood is not very porous with final sanding at 150 grit.

3. How long should I wait after an oil-based stain before applying the BM Stays Clear? I believe I gave it 48 hours last time.

4. I’m a man of patience and detail but I think applying poly just isn’t my thing. I find that this stuff drys while I’m applying it. It says to apply thin but I find that leaves brush marks. Given the large area of the treads, would a roller be a good idea or should I just pick up a new brush? It wasn’t horribly bad but nothing like the streak free coating in your images.

I apologize for the lengthy post. Hopefully someone can point me in the right direction this time around.

Thanks,

Sean

Sean,

Sorry for all the trouble you are having. It sounds like you did everything right just the color wasn’t what you were looking for. Matching the look of two species like oak and maple isn’t easy.

What sort of sealer are you using?

Your application of stain and clear coat sounds like it was good, next time try a pad for applying the clear coat, its much easier to get streak free than a brush. http://amzn.com/B000BZWW8W

Hi Tommy,

Thanks for the reply. I’m not very well versed in sealers, is this something that goes on after I’ve completed staining and prior to the poly? If that’s the case, I haven’t been using one. I applied the BM Stays Clear 48 hours after my final application of stain.

If I should be using a sealer, can you recommend one? I’m using an oil based stain if that’s at all important.

I did use a Varathane wood conditioner prior to staining but I suspect that isn’t what you’re referring to.

And thank you for the link to the pad, I did try something similar to that before which did a decent job. However, I’ve decided to give an HVLP a try this time around if my practice runs go well.

Thanks again,

Sean

The wood conditioner was what I was referring to, I normally use a shellac or oil based sanding sealer. Oak isn’t as susceptible to blotch as are others like maple, and usually stains easily. Time to recoat seems fine on the stain. Are you planning on stripping and re-doing everything? Not sure if you have the treads dry fitted and planning on spraying them that way or if you are masking.

The pad works great I use it to edge all the flooring we do, and a t-bar for the open areas. You can really get a nice film build and it lays the coating off really nice as it dries.

Thanks for clarifying on the conditioner.

The treads are already installed but I’ve removed the railings so I have plenty of unobstructed space. I was planning to mask and spray but I’m not looking forward to the prep so I’m going to give your pad recommendation a try on some scraps.

The only issue I’m facing now is that I need to use the tinted poly again. I finished staining the treads today and I’ve come to terms that getting to an acceptable shade just isn’t going to happen without a tint. We have a modern greyish shade to our maple which has proven quite difficult to match. The tinted poly got us to the most acceptable shade because it masked the red hue that’s coming through the oak. As an added bonus, it made the grain pattern more subtle.

Would you recommend the pad for the tinted poly or prefer to spray it? When using the pad, should it be fully saturated?

I hope I’m not imposing now. I really appreciate the time that you’ve taken to answer my questions.

Sean

Sean

If I were trying to shade or tone like you are doing I would probably spray it. You can mix dye with several things for spray application. I would use a 50/50 mix of dewaxed shellac and denatured alcohol as a vehicle for the dye.

Watch this video it shows the principle of toning.

http://www.youtube.com/watch?v=cC1cHxUf8kc

Tommy,

I just wanted to stop by to say thank you for all your help. After watching that last video, I decided spraying wasn’t for me. It just seemed much too risky for an amateur, especially given that this was my second time around. I ended up going with the Shur-Line pad which you recommended. I cannot believe the difference that it made, I wish I had spoken to you prior to my first attempt!

I was able to get a virtually streak free appearance using the pad. If there are streaks, you need to get pretty close to see them. Perfectly acceptable in my books and definitely better than what the builder had left me with. The only complaint I would have with the Shur-Line is that it creates a lot of bubbles going in and out of the tray (perhaps my technique?). Thankfully though, no bubbles on the finished product which detract from the look.

I ended up having to tint the poly again to get an acceptable color. I did a coat of clear, followed by a coat of tinted poly and finished up with a final coat of clear as per the video. I had to dilute it every so slightly with water to make it workable but it still had my heart racing. Thankfully, everything turned out the way I was hoping and I couldn’t be more grateful for this blog and your assistance.

Sean

Thanks for the follow up Sean, glad to hear it worked out. We are fortunate to have members like Tommy who contribute their knowledge here!

Yes thanks for the follow up. Really glad things worked out well and the end results were what you wanted. Glad to hear back from someone!

Hi there,

Wondering if anyone can give me some tips on applying the Ben. Moore stays clear poly in low lustre.

We are refinishing our floors in our 960 sq foot house. We have what I believe are white oak floors, we sanded with 25, 36, 60, 80 and 120 grit.

I applied one coat of Saman water based stain in dark walnut using a brush. It was a long 10 hour day applying it, but the product was easy to work with. The edge re-wets itself when you come back to a section, so I had no issues with overlap marks.

The stays clear poly is another story! I am using a brush for the edges and rolling the rest. My sister came to help once I realized how fast it dries, I knew I needed help. I tried to use a pad, but found that even more tricky, so went back to the roller. I am doing small sections about 3 by 5 feet or so, and once I move to the next section, the last one has become tacky, and where the two sections meet looks like a sticky mess! I watched some video tutorials on how on roll on poly, but maybe I’m missing something? Is this product usually sticky after about 2 minutes? Should I try thinning with water? How can I avoid overlap marks?

I’m also having problems with little specs of dust landing on my floor and then working into the poly. Because the poly dries so quick, it’s hard to grab the spec of dust and fix that area. I thoroughly dusted and vacuumed before staining, and even had my vents cleaned to avoid this problem! Any spec of dust is showing up immediately because my stain is so dark. We were trying to grab any specs with a tack cloth right before the poly, but it seemed impossible to get them all.

Is sanding between coats a necessary step? Do I sand it by hand if I don’t want to rent the buffer/screening disc? Which grit should I use? I am afraid of sanding because I seem to be having such issues with dust in this house, and even with thorough vacuuming, I don’t want any more dust in the air landing on the floor before the next coat of poly. Although the floor seems very rough still, will sanding between coats make the floor smoother in the end?

Also wondering how many coats of stay clear I should apply? This article had mentioned 4, the can says 2-3. How long between coats? The can says 2 hours, but that can’t be right. How long until we can put furniture in after the final coat? Hopefully 3 days us enough because we have to move in on the 30th and I’m guessing I need a couple more days for 2 more poly coats.

Thanks so much to anyone who takes the time to read this!

Any advice is appreciated!

Kari

Hi Kari, sounds like you are doing everything right, hopefully one of our readers will respond soon! Thanks

Has anyone dealt with the paint chemical odor that lasts for weeks with Stays Clear. Have doin be everything to eliminate and mask it but all have failed. Anyone else have the same problem and if so how’d you fix it??

Bill, Usually about two weeks for a cure on stays clear depending on conditions. The smell should be gone by then.

Thanks Tommy, have one cottage that has smelled for about three to four weeks. Seems to have diminished some but still there and reasonably strong. Any ideas if it continues??

I used it on my floor and can see the roller marks I used a sponged roller and did it twice! What should I use or do to get ride of the roller marks

Hi Ketty,

Unfortunately this is what happened to me too. Roller marks. This product leaves roller marks because it is water based and dries VERY fast. I tried lightly sanding/buffing them out, but they are there for good. We had to just live with them. It stinks, our floors look DIRTY and they are not. After consulting with a professional about our screw up, they said we would have to basically re-start. Re-sand, re apply the stain and re poly. To do it correctly, you cannot STOP at all with the poly. They said use a sheepskin applicator work in long strips from one end of the room to the other, work very fast to keep a wet edge, do not let your edge dry or you will leave marks. In order to do this properly, you really need to be experienced. We found this out the hard way. Sorry!

that makes me kinda sad, I will try to re sand a little and put more on my roller and try the sheep skin 🙁 if it works I will let post it here for others, where there’s a will there’s got to be a way 🙂

Can you apply a flat polyurethane over a low luster? I am working on a cabinet project and used Benwood acrylic polyurethane – low luster over BM Advance latex paint. Still getting too much sheen, I’m thinking of reapplying a flat finish polyurethane. Do you think this will work?

We had our new red oak hardwood floors done professionally. We had them stained with one coat of Minwax pickled Oak stain and then finished with the Benwood low luster Stays Clear. The color is exactly what we wanted but it is bubbling and peeling all over the place! What would cause this?

The Minwax was not completely dry and solvent was still evaporating causing bubbles or blisters. Loss of adhesion due to solvent evaporation. What was surface and air temperature, and interior humidity? The pickled Oak may have micronized wax in it as well, causing poor compatibility and lack of proper surface for acrylic to adhere. Oil based stains should cure out longer before an acrylic is applied. Acrylics have high ammonia content and can amber when ammonia comes in contact with alkyd that is not set up or sufficiently dry or cured.

Thanks Jeff for your response!I believe most failures do occur to improper prep and application, not intentionally, but due to lack of a deeper understanding of how products work.

Hi, I have recently painted a 12 string guitar with a very bright white and have stenciled some black wolves on it. In the past I have used a lacquer. The problem with some lacquers is that it yellows. I was thinking of using Stay Clear water based urethane as it stays stays really clear. I would like to thin it out 10% and spray it right on the paint. Would you know if this will work or do you think eventually it will flake off? Any help will be welcome.

Max,

I am not sure you won’t have yellowing with this product as well, its not made to be applied over paubt. There is actually a post above about yellowing.

Hi Tom thanks, I bought it as the site where it is being sold says it is non yellowing.

http://www.benjaminmoore.com/en-us/for-your-home/paint-products/benwood-stays-clear-acrylic-polyurethane

I have not opened it yet so I can return. Is the link above the same product we are talking about?

Its non yellowing over stain or sealed wood but when applied over paint that changes. What product did you paint with? It may be possible to apply an acrylic lacquer over without yellowing.

I would contact tech from the paint company you used and see what they have to say.

I have been using a nitro-cellulous product. Gives excellent results. Th drawback is I have to do it away from a flame and not in the cold. It is very cold where I am and the stuff sticks to high heaven. I was hoping that a water based urethane would work. Thank you for the heads up. I’d hate to ruin all the work done. Now to find a replacement. I will look for an Acrylic Lacquer hopefully that does not yellow at all. I want to keep the High White I have. Again thanks

Hi, I am considering using this water based to finish off my reclaimed wood floors. They are very rough with saw marks nail holes Ext. What would my best way of applying be and would I need to sand in between coats?

Thanks Jason

How long does it take to dry? Also I have formaldehyde laden laminate from Lumber Liquidators. Will this help seal in the formaldehyde?

I’m a rookie at this so here my question. I have some southern red cedar that will be installed as ceiling in my bedroom. Will it hold the color of the cedar long term & does it have to be sanded between coats? I want the semi rough look on the ceiling just want a product that will hold the color or the cedar lower the smell of cedar and not continue to release fumes of it’s own.

Sorry not sure if my first email was sent I’m a rookie at this. I have some southern red cedar that will be installed in my bedroom for a ceiling. Will this product allow the cedar to keep it’s color? I planed the boards so do I have to sand between coats? I do not want it to be real smooth. Will it help prevent the strong cedar smell? Does it have strong fumes? What is the best and easiest way to apply coats. I was hoping I could apply the first coat before I install the cedar then do a touch up second coat only on areas that it may be needed.

Carrol

Love the product. Applied multiple coats of Gloss Stays Clear on plywood floors and they are BEAUTIFUL. THe floors pop with definition. EAsy to maintain, non yellowed and they cure well and hard. GO gloss and never see dust.

Hi There

Can i spray this product with my HVLP sprayer

I would assume i will need to dilute it

Can i dilute it with water or what do you recommend

Peter

I highly recommend Bona Traffic Natural for a matte finish.

Just applied 3 coats of Benjamin Moore Stays Clear to a pine floor that was re-sanded and stained.

Wondering how long we should let it cure before putting furniture back on it.

Stays clear is the worst fake poly product I’ve ever used. I’ve owned my own company since 1993. I do not believe the reviews of people using it on floors. It has no build. If you expect to build desirable gloss in three coats…expect to put on 9 coats. It’s crap. The finish my clients desire is without imperfections. This is impossible with this horrible product. If you have to use fake poly…use OLD MASTERS ASCENT. You can achieve desirable finish in less the half the coats. I use Ben Moore products daily, but will never use stays clear again. It is a ridiculously bad product.

what do you find works best? how about Verathane?

Hi, I just saw a post on Facebook for this product. They said that it was applied a year ago on a pine staircase and that it was peeling up. I like and use a lot of Benjamin Moore products in my line of work so I am curious to know what could cause these problems. I have a photo of the post I would like to send you. Can’t post them here it seems.

is w423 benwood acrylic polyurethane a water or oil based product.

Years later I want to paint fresh coa h of while over stays clear, how do I prep the surface? Sand or just wash and paint over it.

wondering how your Stays Clear has held up? do you think it would be the best product to use for the following: on plywood floor that has been latex primed, painted probably with Benjamin MooreFloor & Patio Latex Enamel in flat, and then a faux finish on top of that using 1 part latex with four parts glaze? I am searching for the best glaze to use so would appreciate suggestions.

I’m confused, I am using this product for the first time on a coffee table, and if I attempt to sand in between coats, it starts to peel off.

The coffee table was previously finished, but I washed, stripped, bleached, neutralized, dried for 3 days, stained with minwax stain and then several days later applied stays clear. Goes on beautifully, love the finish, but I didn’t dare sand in between coats after I tried and failed the first time and had to entirely strip the top of the coffee table’s finish off and restain before sealing again. I’m wishing I went with a wipe on poly that hardens and cures quickly. Stays clear resembles PVA glue to me. I can’t think what I could be doing wrong, can you?

This time I applied two coats of stays clear in low lustre WITHOUT sanding inbetween.