Airless sprayers are the perfect tool for high production needs.

They are often used in large scale commercial painting and for good reason. They will allow you to paint a large building in less time. While they are a great resource for commercial painting, they are often a large expense and it is critical that you select an appropriate unit to match your painting needs. We will explore the two most important things to consider when choosing an airless pump to ensure you find one that will properly meet your needs and last a long time.

How much pressure do you need for your spraying process?

Pressure provides a few different things that help in your painting process. One it provides the ability to supply a coating over a distance. If you will be painting long distances from your pump you will want to find a higher pressured pump. The other thing pressure allows for is supply and break up of high viscosity paintings. If your coating will be highly viscous you will need a higher pressure pump to supply the coating and appropriately atomize it. For an idea of pressures required heavy body latex coatings typically need at least 2000 psi to be properly atomized. To clarify a high pressure pump would be at least 30:1 in ratio, meaning for every 10 pounds of pressure supplied to the pump the pump would output 300 psi of pressure. Typically a 30:1 pump can provide coating up to 200 feet from the source, if you will be further than this from your pump a higher pressure rating will be needed.

Pressure provides a few different things that help in your painting process. One it provides the ability to supply a coating over a distance. If you will be painting long distances from your pump you will want to find a higher pressured pump. The other thing pressure allows for is supply and break up of high viscosity paintings. If your coating will be highly viscous you will need a higher pressure pump to supply the coating and appropriately atomize it. For an idea of pressures required heavy body latex coatings typically need at least 2000 psi to be properly atomized. To clarify a high pressure pump would be at least 30:1 in ratio, meaning for every 10 pounds of pressure supplied to the pump the pump would output 300 psi of pressure. Typically a 30:1 pump can provide coating up to 200 feet from the source, if you will be further than this from your pump a higher pressure rating will be needed.

What size tip and how many operators do you hope to run?

In order to preserve the life of your airless sprayer you should aim to size it to run at about 25 – 40% of its recommended Gallon Per Minute (GPM) maximum capacity. Your fluid flow rate will be determined by tip size you will use and the number of operators that you want to use the pump at a given time. By keeping the pumps use only to a portion of its total capacity it will cycle less frequently allowing for the life of the pump to be extended. The other reason you oversize a pump for your application is over time your airless tips will wear which will cause your sprayer to use more gallons per minute of paint than the tips original stated GPM requirement and you need an oversized pump to accommodate this additional fluid rate the tip will use. In addition to the tip size the number of operators will affect the fluid rate requirements. Each additional operator will essentially double the GPM requirement. If one operator needs a 0.5 GPM pump two operators will need a 1 GPM pump.

Where are you Painting?

The availability of a source to supply energy for airless spraying will also be critical in determining the proper sprayer. If you are in new construction often times their will not be electricity available. If this is your situation you will most likely need to consider a gas powered airless unit. If you are painting in an established area with readily available electric you can evaluate between electric or gas engine driven airless (or a hybrid). If you know you will paint both in old and new construction the best choice is an airless that will allow you to use the unit both with electric or gas as the energy source. Additionally where you will paint will be important in choosing between a Hi-Boy or Lo-Boy style sprayer. Hi-Boy sprayers are easier to move around on a job site due to having a handle that comes up closer to your chest, but they are more difficult to transport in the back of a small vehicle. A Lo-Boy is easier to transport in a car as it takes up less room but is not as easy to move around once at the job site due to not standing far off the ground with the handle in place. One other pertinent difference between the Hi-Boy and Lo-Boy is that the pickup tube is a single piece with a Hi-Boy where a Lo-Boy utilizes a flexible hose that is fed into the coating source. The bottom line is if you will be moving a lot on the worksite without packing the sprayer a Hi-Boy is probably right for you. If you are moving between a lot of smaller job sites and not moving within a job site much a Lo-Boy is usually a better choice.

The availability of a source to supply energy for airless spraying will also be critical in determining the proper sprayer. If you are in new construction often times their will not be electricity available. If this is your situation you will most likely need to consider a gas powered airless unit. If you are painting in an established area with readily available electric you can evaluate between electric or gas engine driven airless (or a hybrid). If you know you will paint both in old and new construction the best choice is an airless that will allow you to use the unit both with electric or gas as the energy source. Additionally where you will paint will be important in choosing between a Hi-Boy or Lo-Boy style sprayer. Hi-Boy sprayers are easier to move around on a job site due to having a handle that comes up closer to your chest, but they are more difficult to transport in the back of a small vehicle. A Lo-Boy is easier to transport in a car as it takes up less room but is not as easy to move around once at the job site due to not standing far off the ground with the handle in place. One other pertinent difference between the Hi-Boy and Lo-Boy is that the pickup tube is a single piece with a Hi-Boy where a Lo-Boy utilizes a flexible hose that is fed into the coating source. The bottom line is if you will be moving a lot on the worksite without packing the sprayer a Hi-Boy is probably right for you. If you are moving between a lot of smaller job sites and not moving within a job site much a Lo-Boy is usually a better choice.

Brand choices

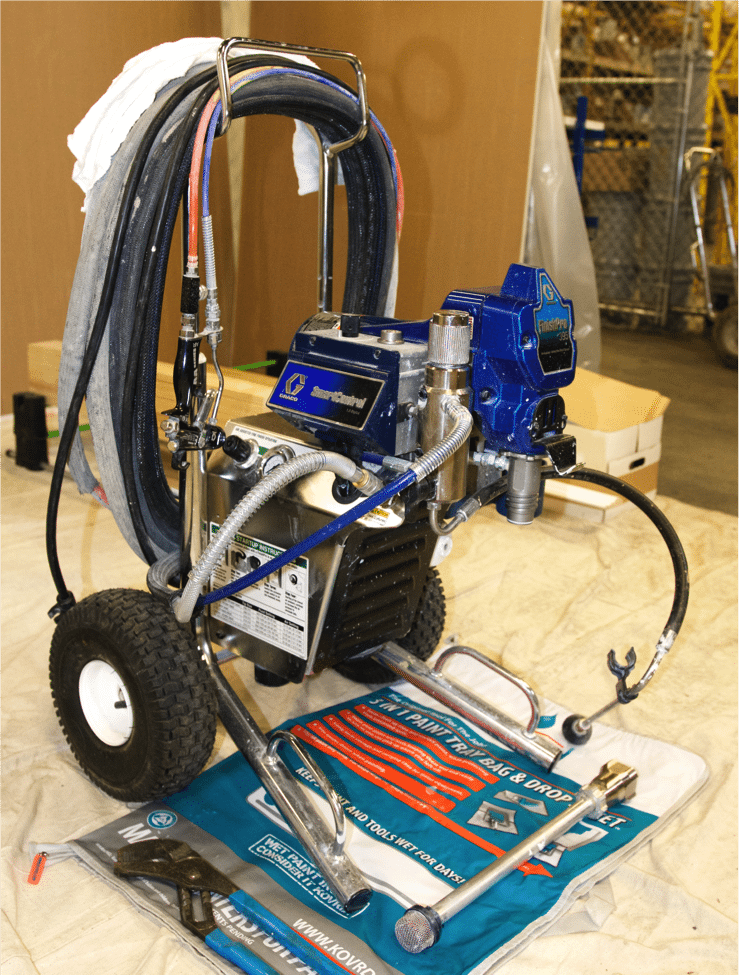

The two largest providers of airless equipment are Titan and Graco. They are both excellent machines and choosing one over the other comes down to a few things. First check your local area to see where the nearest service center is. The last thing you want is a pump to fail and not have a knowledgeable repair center that can help with diagnosing and if needed rebuilding the pump. Additionally see if they carry or will carry the most frequent trouble area parts in stock so that you do not go without a sprayer if an issue arrives. Evaluate the brands warranty options to see if they may make more sense to go with one over the other. Also be aware that certain brands tend to be stronger in certain categories Titan is known for its electric airless and line stripers, Graco is well known for their large Airless Sprayers. Finally make sure they have a solution that matches your GPM and pressure needs, if you can match your proper GPM and pressure needs but not go over your required GPM and PSI significantly you can save significant money on your sprayer purchase.

Do your research

If you are in the market for an airless sprayer make sure to have a good idea of where you are most likely to paint, the tip size you will use, how many operators will paint simultaneously, the pressure you will need, and where you can find good support. By knowing this information ahead of time you can make a better airless purchasing decision allowing for a long time of headache free painting.