Dry-ice blasting is one of the most efficient cleaning methods that deeply removes the surface of any items or equipment. The process is operated similarly to abrasive, sand and soda blasting. The carbon dioxide gas emulated through blasting the dry ice at a low temperature and high-speed process. After the surface has been blasted, there will be absolutely no residue of water, sand, grit and chemical reactions.

Dry-ice blasting is one of the most efficient cleaning methods that deeply removes the surface of any items or equipment. The process is operated similarly to abrasive, sand and soda blasting. The carbon dioxide gas emulated through blasting the dry ice at a low temperature and high-speed process. After the surface has been blasted, there will be absolutely no residue of water, sand, grit and chemical reactions.

It is a safe procedure because of its fire-resistant and nonconductive features. Hence, it is an ideal option for cleaning electrical machines in which other blasting methods cannot offer. With these several outstanding features, it is substantially known to have the most extensive functionality. It is primarily used for food preservations and in other manufacturing industries.

However, this method can also be used in residential areas. Residential or Commercial Painting Contractors can take advantage of the different applications of dry ice blasting when preparing areas for painting.

Here are the parts of the house that can benefit from dry-ice blasting:

- Furniture – Dry ice blasting can provide a smoother surface for wood furniture. They can then be transformed with a newly furnished look or restore its original appearance. It would also help to eliminate the previous layers of paint. It also opts for reshaping and decorative purposes. It can be done within a short period without any debris left on the surface.

- Windows – Windows are one of the fixtures inside the house to be frequently affiliated with molds. Most significantly those which are made up of wood. These molds lessen the value of the window and hinder it from being aesthetic. Dry-ice blasting is considered to be an excellent option for completely removing the molds and other damages on a window. It will clean not only the top surface of the wood but also the deep roots.

- Kitchen tools – The kitchen area must always be kept from any dust and dirt for it is the place where food production takes place inside the house. Keeping it sanitized will reduce possible health risks and other severe damages. Any chemical spills or stains must be removed. Kitchen tools which include grills, ovens, and vents can be quickly and deeply cleaned with dry-ice blasting. Unlike the other blasting methods and as stated earlier, the use of dry-ice provides a chemical-free surface after cleaning which is suitable for kitchen tools. Maintaining the cleanliness of these tools are highly significant for it the foods are being processed on it.

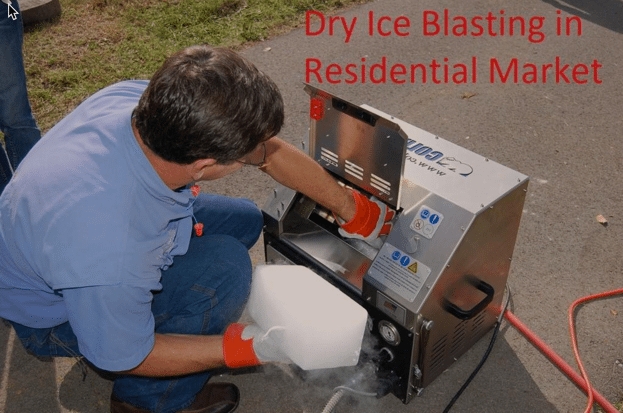

Dry-ice blasting needs high-quality and heavy-duty equipment that is capable of handling supremely cold dry ice. You should consult a professional who is specifically trained to use the equipment. They must have a sufficient experience to ensure the safety and success in the midst of the process. Compared to the other cleaning procedures, it is more affordable and a highly valued service.

What if a painting contractor wanted to use this method?

Mastering the dry-ice blasting process necessarily demands technical skills and knowledge. Hence, there are specific companies that focus on serving their clients with an outstanding dry-ice blasting method. However, some painting contractors have a dilemma on whether to utilize the process with or without professional help. When making a decision, the capability of the contractor must be thoroughly evaluated first for it includes various complicated phases. There are regulations, terms, and conditions that must also be followed to prevent such severe consequences.

What steps would he take?

A skilled dry-ice blasting contractor who specializes with this method is primarily trained. With the reason that it involves heavy duty equipment and chemical substances, one must be able to know how to manage and use the tools throughout the process correctly. Having insufficient capacity may only cause damages. A painting contractor can learn the method by applying to one of the several companies that relevantly discuss and instruct the ways on how to operate dry ice blasting.

Do you have to be certified/licensed?

In part with all the information stated earlier, the contractor must be legally certified to perform the method. One cannot simply learn and practice the process without a competent education. To gain authorization and rights, there must be enough experience and learnings. With these attainments, clients would be more convinced about your abilities and services. They would be able to identify your profile and expertise.

Dry-ice blasting method is a complicated process that highly requires professional help. It would be wise for a painting contractor to acquire a reliable and excellent dry-ice blasting service. Since it is an entirely different procedure, it cannot be easily done with the collective knowledge of a painting contractor. It may also result in additional and unnecessary costs. Therefore, it is more efficient to hire a particular contractor who specializes in this kind of blasting.

Frank Crawley is a father of two children, an architect and a writer in Albuquerque.

“I love sharing ideas as much as I love coffee”

You can visit his blog at Coatypes – Types of Coatings.