Large scope projects are never simple

Industrial painting on an elevated water tower is a great deal more involved in the aspects of planning, logistics and safety. When you get down to it, painting is painting. With qualified painters and depth knowledge of the overall painting process, almost anything can be painted! Last year, we painted two elevated water towers. Each tower had its own challenging aspects and details requiring a significant amount of planning. Let’s focus on the larger of the two towers, which was 185’ tall.

When painting an elevated surface of any kind, safety is always top priority.

On most typical jobs, a contractor may need to access heights of forty to eighty feet. Those heights are easily accessed by standard size AWP (boom) lifts. Anytime you have crews in AWP’s, it is crucial everyone has been trained extensively. OSHA mandates any lift operator be trained and carry a pocket card at all times. Make sure your crews have all the proper PPE as well. Depending on the scope of the project, PPE could include any or all of the following: harnesses with lanyards, safety lines, glasses, gloves and respirators. When working at extreme heights, it is important to have an OSHA certified “competent person” on site. In addition, anyone who is getting out of the lift baskets when up in the air needs to be “climb” certified. This is specialized training regarding climb safety, three points of contact safety, proper safety line attachment, and rescue procedures. Custom Coatings Inc needed three sizes of lifts for this project: one 150’ boom, one 120’ boom and one crane with 250’ of stick. Once safety training has been addressed and utilized, you can confidently move to the more exciting aspects of the project.

The key part of any successful paint job is proper preparation.

In the case of this tower, it needed a thorough cleaning. We blasted the tower with 4000 psi pressure washers and used zero degree oscillating tips to help “chew” through some of the loose scale and rust. We used industrial degreasing detergents and bleach to aid in cleaning. We knew some of the minor surface rust did not have to be prepared in great depth due to the coatings we were using, but the heavily pitted rust was given SSPC-SP3 power tool cleaning procedures (SSPC is the Society for Protective Coatings and provides industry standards for proper painting on concrete, steel, and other industrial applications). Due to the client’s specifications and expectations, this tower did not need to be blasted down to bare steel. This particular tower was no longer functional. The client’s goal was to have the tower act as focal piece for an urban industrial housing/commercial development.

Once the tank was cleaned and fully prepped, we applied a Sherwin Williams 100% solids product to the heavy rust. This product is specifically engineered to lock in rust on marginally prepared surfaces. After the initial pre-prime, we applied a full coat of Sherwin Williams Duraplate 235 epoxy coating. This product is extremely durable and is often used on offshore applications. We applied the first coat at 5 mils dry film thickness. We then applied two full coats of Sherwin Williams Corothane 1 urethane coating to the entire structure. This extreme high quality urethane will provide years of durable glossy protection to the tower. All coats were applied by spraying and back rolling so the materials were evenly distributed for a uniform finish.

On a tower of this size we would normally use the tie off points which are engineered and built into the top of the tower during initial construction. These points are used to access the top and high sides lifts cannot reach. Upon inspection, the top tie offs were ruled out as an option due to the age and wear. We utilized a crane with 250’ of stick and a man basket to get us all the way across the top of the tank and upper sides. The crane also made it easier to install the stencil we used to apply the clients logo on the tower. The stencil logo was made up of nine 4’x8’ pieces of polystyrene. These pieces were applied starting at the center of the tower and secured down so we could properly paint the logo. This might sound like a relatively easy endeavor, but imagine being 175’ in the air, standing on a tight 18” catwalk or in a 4’x4’ crane basket, and holding a 4’x8’ sheet of thin material over your head which basically acts like a sail! This phase required extra attention to our safety procedures to ensure our painters well-being.

On a tower of this size we would normally use the tie off points which are engineered and built into the top of the tower during initial construction. These points are used to access the top and high sides lifts cannot reach. Upon inspection, the top tie offs were ruled out as an option due to the age and wear. We utilized a crane with 250’ of stick and a man basket to get us all the way across the top of the tank and upper sides. The crane also made it easier to install the stencil we used to apply the clients logo on the tower. The stencil logo was made up of nine 4’x8’ pieces of polystyrene. These pieces were applied starting at the center of the tower and secured down so we could properly paint the logo. This might sound like a relatively easy endeavor, but imagine being 175’ in the air, standing on a tight 18” catwalk or in a 4’x4’ crane basket, and holding a 4’x8’ sheet of thin material over your head which basically acts like a sail! This phase required extra attention to our safety procedures to ensure our painters well-being.

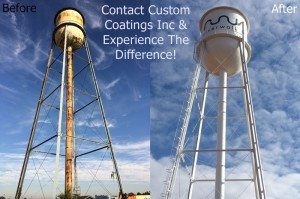

The finished product is not only an aesthetically pleasing upgrade, but it lends the industrial feel our client envisioned. The tower may not be functional in its original sense, but it will serve our client’s vision for many years to come. At Custom Coatings, Inc., we pride ourselves on the successful merging of client’s expectations and our safe and professional executions.

*** Visit Custom Coatings Inc Industrial Photo Gallery to view all pictures from this Elevated Water Tower Painting and other projects:

http://www.customcoatingsinc.com/industrial_photo_gallery.htm ***

Excellent work, Patrick! Quite the challenge. Thanks for sharing.

Thanks for the kind words Lisa! We really, REALLY like the challenging work! It helps break up all the regular painting we do the rest of the year.

What does a project like that cost?

This was in fact one of our most challenging projects in the history of Custom Coatings, Inc. I am always concerned first about our guys safety and though I know they are trained and safe………………….its 185′ in the air!!!! A lot can go wrong. We had no issues with safety and now we can say this is likely the coolest job we have completed to date.

Nice project. I enjoyed reading it Pat.

Thanks Tommy! If you see any water towers in your area that need painting shoot me an email and we will go get it!

Great project Patrick and Joe. On these types of jobs everyone needs to be on their toes at all times. Which means having a good team and good leadership is crucial. Clearly Custom Coatings inc. has both.

Kudos to everyone that was involved on this water tower painting project!

Thank you for the kind words Paul – we do our best to keep our crews safe and busy!

Wow, wow, wow that is beautiful work! Fresh water from a fresh looking tower!

You guys are amazing. Kudos from Virginia

Thank you Anita! We have painted other water towers, but we have just copied logos already in place. This was the first time we installed a new logo. The owners were happy and we were pleased with the outcome!

Wowza, that really is impressive. Very well done!

Thank you Brian!

Nice Work Patric! My name is Drini and I have a couple questions and i could really use your help. Here is the sum of it: I have been working for a company painting and blasting water towers for 15 years. On the job I know how to do everything from blasting, painting, containment, welding and etc. I am young and very ambitious and for a couple of years i have been contemplating opening up my own business. For starters i want to start small like pressure wash, recoat, power tool outside as well as spot blasting to full blasting interior and of course painting. My main concern would be getting the jobs and the bidding. the business management like paperwork is also going to be challenging but I’m worried about finding the jobs and the bidding on the jobs. If you would be so kind to help me out with some advice i could really use it and appreciate it. my email is dgjini86@hotmail.com I know your busy with work and everything so anytime you like please help.

My father did this type of work decades ago, though not with the sophistication you eloquently describe.

He used to explain that he would do some welding or painting on a “Set of Falls”. I was trying to understand that better but can not find the term being used. Do you know another name for that contraption?

he was talking about block and tackle rope falls with a seat board . look that up and it should show you some images .

Hello. I am trying to figure out who I should talk to about an ugly water tower that I feel needs to be painted in my hometown. Any advice?

Hi Jessica, I would suggest you contact your town’s public works department. Thanks

Hi Patrick,

If you are aware of any water tower painting companies that have any overspray problems, we would appreciate your referring us to them. It is said we are the largest and oldest overspray removal company in the nation having been in business for over 50 years and having removed overspray from an estimated 300,000 vehicles, many of which were affected by the painting of water towers. Our hand removal of epoxy and urethane water tower overspray from vehicles is very effective eliminating the need for affected vehicles to be re-painted. Our website is http://www.overspray.com.

We thank you in advance for any referrals you can send our way.